Consumables: Filters, Seals and Load Cards

Product Showcase

Information

SteriTite® container tamper evident seals, filters and load cards provide assurance that sets are processed, identified, and tamper proof. Container seals are available for steam and low temperature sterilization cycles. SteriTite® Indicators and load cards are identification tags placed in dedicated slots on containers. The indicator changes colors when sets are sterilized.

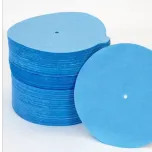

SteriTite® sealed containers require single use filters to create a bacterial barrier. Use paper filters for rapid processing for terminal steam sterilization. Polypropylene filters are universal and required for H202 sterilization including use in STERRAD®, V-Pro®, Sterizone® and other hydrogen peroxide systems. SteriTite® sealed containers require single use filters to create a bacterial barrier. Use paper filters for rapid processing for terminal steam sterilization. Polypropylene filters are universal and required for H202 sterilization including use in STERRAD®, V-Pro®, Sterizone® and other hydrogen peroxide systems.